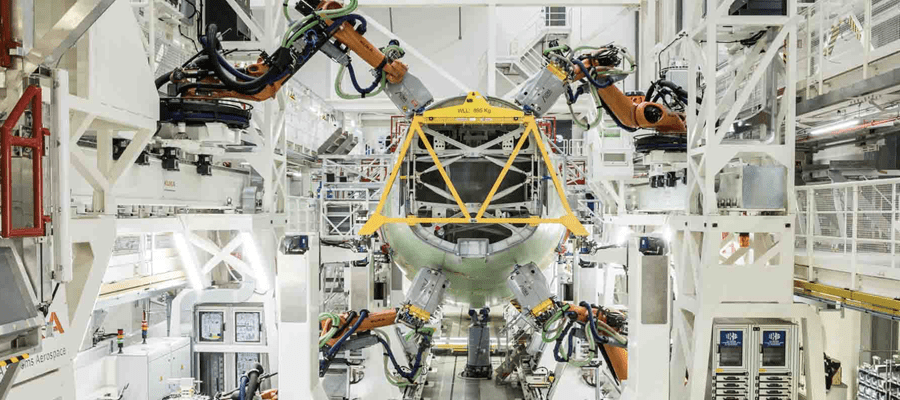

Airbus has introduced a new automated fuselage structure assembly line for A320 Family aircraft in Hamburg. With a special focus on manufacturing longer sections for the A321LR, the new facility features 20 robots, a new logistics concept, automated positioning by laser measurement as well as a digital data acquisition system. These will further support Airbus’ drive to improve both quality and efficiency while bringing an enhanced level of digitalisation to its industrial production system. Michael Schoellhorn, Airbus chief operating officer, commented: “By embracing some of the latest technologies and processes, Airbus has begun its journey to set new standards in

This content is restricted to site members.

If you are an existing user, please login below.

New users may register below.