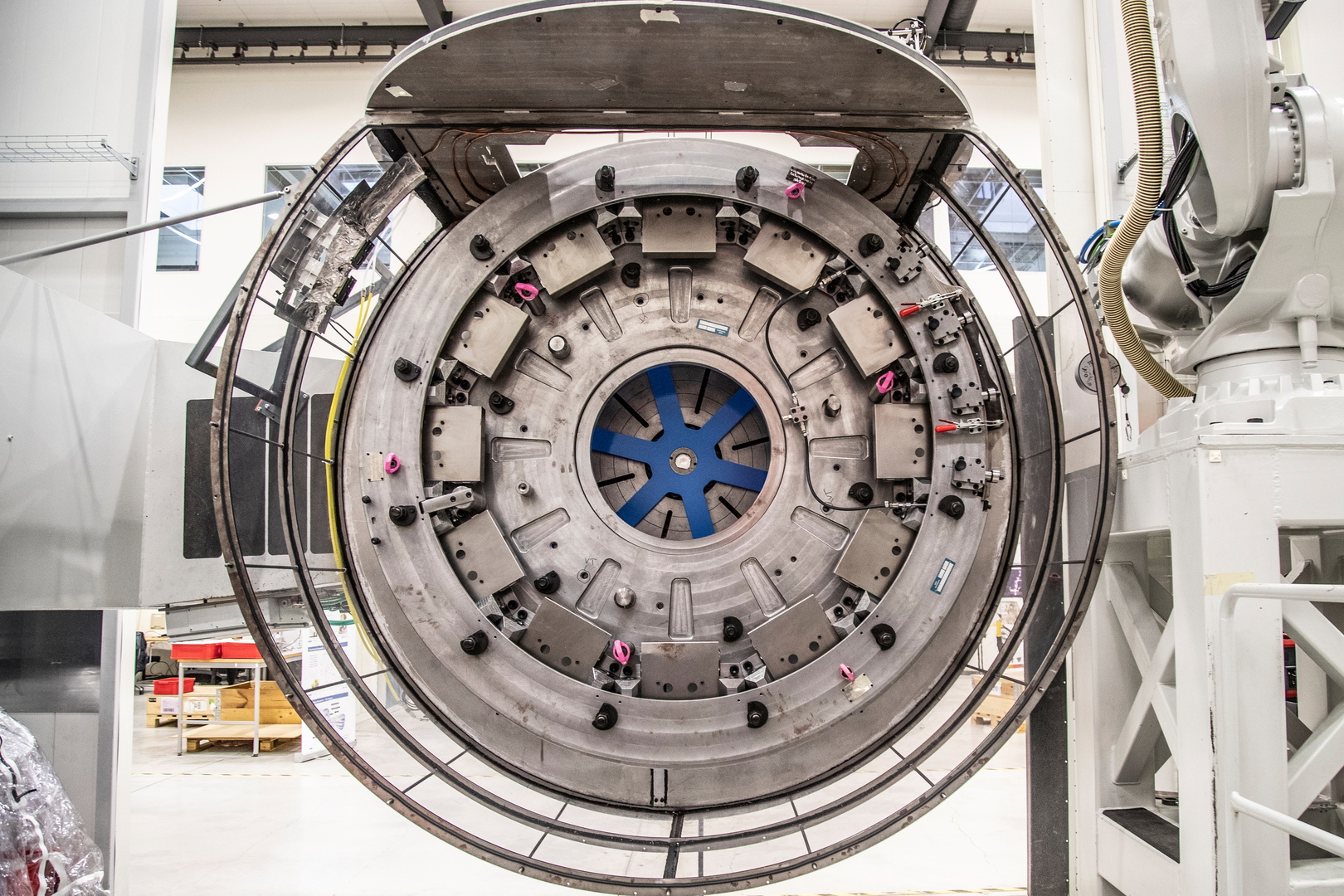

GKN Aerospace has expanded its Newington, Connecticut site with a new production line dedicated to additive fabrication of the fan case mount ring (FCMR) — a critical component for Pratt & Whitney GTF engines powering A220 and E195-E2 aircraft.

The company said its FCMR programme is the “largest flight-critical additive component” to achieve FAA certification and is on track for full serial production by the end of this year.

The process is expected to reduce material consumption, shorten production lead times, and is projected to achieve over 70% material savings. GKN Aerospace this will also “help strengthen global supply chains” by offering an alternative production method.

“The combination of strong local support, the highly skilled workforce and the availability of an aerospace network and infrastructure here allows us to bring our latest additive fabrication technology into industrial-scale production, creating jobs and supporting our long-term relationship with Pratt & Whitney," said GKN Aerospace SVP material solutions Sebastien Aknouche. "We are proving that additive fabrication is not only technically transformative but also delivers real-world benefits in sustainability, lead-time and predictability for our customers.”